The application of computational fluid dynamics (CFD) is at the heart of aerospace design and analysis, necessary for such activities as configuration design and modification, estimation of aerodynamic loads, estimation of stability derivatives, air intake flow analysis and aerodynamic improvement analyses among others.

The next generation of design systems will need to include even greater geometric complexity and higher fidelity simulations while maintaining the same design cycle window. This means executing larger simulations with longer simulation run times at lower costs than before.

Founded by Dr. Ron Ho Ni and located in California, AeroDynamic Solutions, Inc. (ADSCFD) focuses on delivering aerospace-class CFD for the global aerospace industry. Their CFD flow solver, Code LEO, is a density based, explicit time-marching Unsteady Reynolds-averaged Navier-Stokes (URANS) code. Using OpenACC, ADSCFD was able to GPU-accelerate their commercial flow solver software dramatically reducing CFD simulation turnaround time while simultaneously reducing the cost for those simulations.

Challenge

CFD techniques for the accurate prediction of various aerodynamic and propulsion parameters in the design phase is reducing the dependencies on experimental testing, and has emerged as one of the important design tools for aerospace engineering. Enabling the modelling and simulation of flow with full geometric complexities and higher fidelity is paramount; however, the cost in time and compute resources is a limiting factor.

“The design system as a whole is changing very slowly because there are opposing forces working,” said Michael Ni, CEO of ADSCFD. “We want more complexity and higher fidelity analysis in order to make breakthroughs on the research and analysis front, but to do those things you have to use larger meshes and more computers. As we add more computers, we are hitting a parallel efficiency problem.”

With the slowing march of processor clock speeds that was once the predominant CPU trend, ADSCFD had to explore new hardware technology to hit their targets.

“We identified that we hit a limiter and that we needed to get 20 to 100 times faster, but more importantly, we had to do it at the same or lower cost.”

GPUs offered major advantages such as lower cost per thread, increased speeds, and more dedicated hardware specific to high performance computing (HPC) applications, but that would require enabling their proprietary code to be GPU-compatible.

Solution

To utilize the advantages provided by GPUs, the team at ADSCFD chose to use OpenACC.

“We ultimately chose OpenACC because it is easy to add through a directive-based system,” said Ni. “We considered CUDA but decided that it was not portable enough for our needs. OpenACC offered us ease of implementation, compiler improvements that will translate directly into the code, with the added benefit of having the direct knowledge of PGI and NVIDIA engineers to improve our product.”

Results

By using OpenACC to GPU-accelerate their commercial flow solver, ADSCFD achieved significant value. They realized dramatically improved performance across multiple use cases with speed-ups ranging from 20 to 300 times, reductions in cost to solution of up to 70%, and access to analyses that were once deemed infeasible to instead being achieved within a typical design cycle.

For reference, the cost of CFD simulations includes both the physical costs, such as the cost of CPUs, GPUs, memory, hard disk drives, networking and other hardware, and soft costs including power, cooling, IT management, and rack space. Relying on Amazon Web Services (AWS) to distill the simulation costs into a convenient dollar per hour ratio, ADSCFD determined that to run a parallel simulation efficiently the cost is about $0.21/ hour/CPU and about $3.06/hour/GPU or 14.5 times the cost of the CPU.

*CPU-This instance has more than 8 CPUs but when using above CPUs, clock speed reduction occurs and the parallel efficiency goes down by 50%. Thus only 8 CPUs were used in calculating the cost.

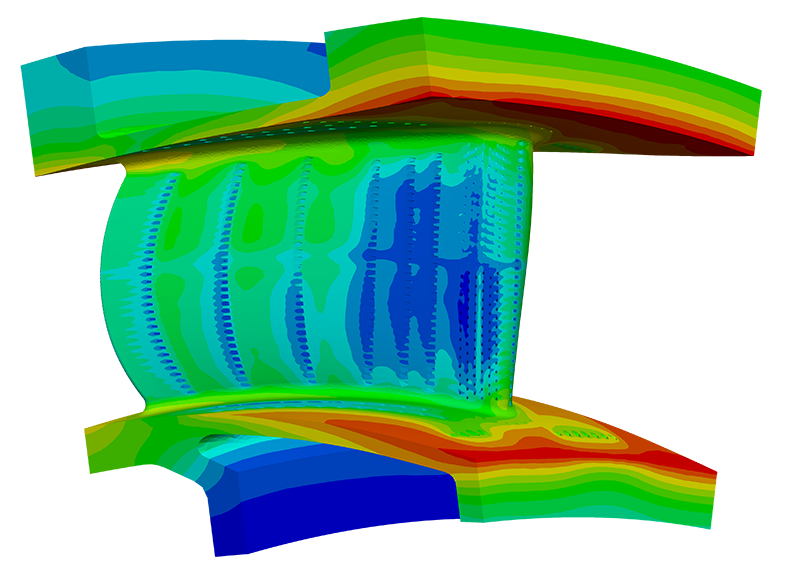

Cooled Turbine Design

Cooled turbine design focus on ensuring that blades can withstand increasing turbine entry temperatures to improve thrust, and maximize overall efficiency. Cooling holes drilled through the airfoil enable cooled air to flow onto the surface of the airfoil, protecting it from the high temperatures emitted by the combustor. For accurate analysis, every individual hole in the airfoil and the inner channel supplying the cooling flow to the holes must be part of the model. By GPU-accelerating their CFD solver, this 50-hour simulation can be driven down to 16 minutes—a 187x speedup—on a single GPU compute node at 62% of the minimum CPU based cost.

“Previously, these analyses were on the fringe of what’s practical during a design cycle because of the amount of time and CPU costs needed for the analysis. At 16 minutes, the analysis has gone from the fringe to being perfect for design optimization loops,” said Ni. “Additionally, we tried to achieve the same speedup using multiple CPUs and found that there was no number of CPUs that could be applied to this case to get the same turnaround time as GPUs.”

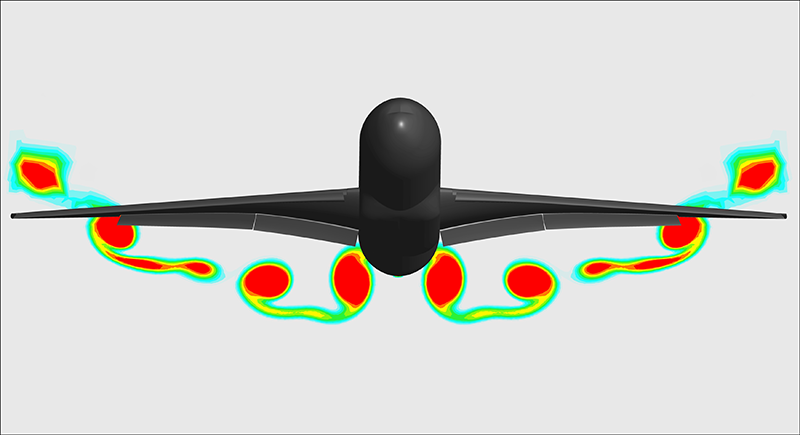

External Aerodynamics

In another use case, an external aerodynamics analysis involving a 27 million element unstructured mesh, ADSCFD was able to reduce the simulation time from 79 hours on a CPU to 18 minutes using 16 cores and 8 NVIDIA V100 GPUs, a speedup of 257x, at 44% of the minimum CPU-based cost. Additionally, they calculated that they would have needed over 1000 CPU cores to match one single GPU compute node.

“Going forward, GPU acceleration using OpenACC will be a focal point of our future development. We believe that the improvements in speed and cost will jumpstart the next evolution of the turbomachinery design system,” said Ni, adding “We expect that faster and more powerful GPUs will make analyses that are currently unachievable well within reach in the next few years.”

About ADSCFD

ADSCFD delivers aerospace-class CFD for the global turbomachinery industry. Built on the innovations of Ron-Ho Ni and rooted in decades of cutting edge aerospace application, the ADSCFD solution suite enables turbomachinery designers to tackle a wide range of compressor and turbine flow problems with confidence. The company is privately-held and headquartered in Danville, CA. For more information, visit www.adscfd.com.